About Global Lift Used Forklifts Mesa

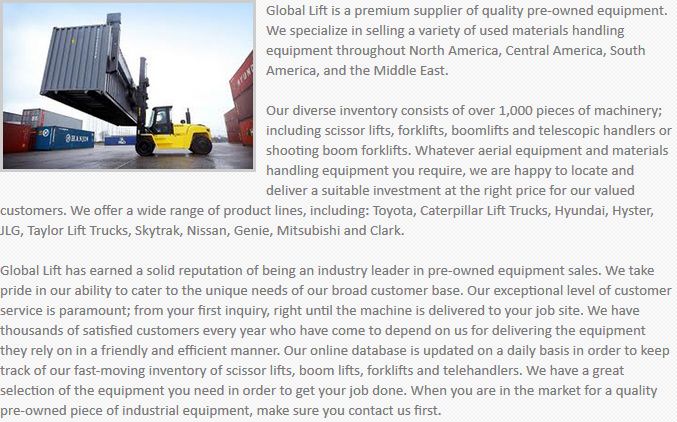

Global Lift Mesa - The following classes of forklift describe the application and fuel option of every forklift. Certification is required for each and every class of forklift which the operator would be using.

Class 1

These forklifts come with either pneumatic or cushion tires. Pneumatic tires are suggested in dry conditions for outdoor use. The models with cushion tires are designed for indoor surfaces which are smooth. These are electrically powered vehicles that use industrial batteries, that make them desirable in closed locations where air quality is an issue. Travel and hoist functions are controlled by transistor motor controllers. These are versatile units usually used everywhere from the loading dock to the storage facility.

Class 2

This forklift is suggested for environments where narrow aisles need to be negotiated. They are efficient at making the most of storage space. Their unique design makes them perfect for small spaces and where speed is needed.

Class 3

These hand-controlled, battery-powered models are designed for the operator to stand in front of the truck and control the lift using a steering tiller. The tiller has controls mounted on top and is moved sideways so as to maneuver the vehicle. The units which have smaller capacity use industrial batteries.

Each and every year, there are around twenty thousand cases of accidents that are related to utilizing forklifts within the United States alone. And every year roughly one hundred deaths are caused by forklift accidents. Luckily, proper training about maintenance and operation procedures could significantly reduce the risk of accidents. The basic safety rules and tips below should be followed whenever utilizing a forklift.

The employer is responsible for making sure that workers are trained to operate a forklift and have gone through a correct training program. Training includes a combination of presentations, lectures, discussions and practical hands-on training. Reevaluation should occur every three years. Forklift operators should be up-to-date with current forklift safety regulations. Forklift training program content includes general workplace hazards, dangers of forklift operations, workplace lighting and surfaces, and dangers related to using the particular forklift which the employee would be utilizing. An employee should be eighteen years of age or over to use a forklift.

Forklift inspections should be carried out on a daily basis to guarantee the safe and proper functioning of the machinery. The inspection involves keeping a checklist of items and reporting any problems immediately.

Having a safe and clean workplace is vital in the safe operation of a forklift. A safe work site means establishing "traffic lanes" which are only designated for forklift use. Warning systems such as horns and flashing lights should be in place to be able to indicate when there is an approaching forklift. Forklift docking stations must be inspected daily and kept in good repair.

General safety rules for forklift use consist of avoiding known hazards on the ground, like oil spills or wet spots; raising or lowering the load only when the forklift is stationary; ensuring there is enough clearance for the load; and keeping hands, arms and legs in the vehicle while utilizing it.

Forklifts are able to lift really heavy things because they have a counterweight on the back of the forklift. The giant counterweight gives balance to the forklift so the machine doesn't tip over when raising heavy cargo. Forklifts are rated according to their load capacity. A small forklift that could lift one thousand eight hundred kilograms weighs roughly four thousand kilograms, which is the same as two full-size pickup trucks. The biggest forklifts can carry stuff as heavy as 36,000\thirty six thousand kilograms.

There are a lot of safety concerns involved in utilizing a forklift. While driving down a ramp, travel in reverse. If the load is bulky and interferes with vision, haul it in reverse. Operators need to be familiar with how to safely mount the lift utilizing the "three-point stance." This involves putting the right hand on the back of the seat, while gripping the upright of the safety cage utilizing the left hand and placing the left foot on the step. Never jump out of a forklift even during a tip over. It is really safer to remain inside the confines of the lift. Any fall or slip on a forklift can cause serious injuries.

In a lot of businesses, the forklift is considered an indispensable as they are required to rapidly lift and move things, unload and load products safely and with little to no physical exertion. Pedestrian safety is a major priority when working in public spaces. Operators must always give pedestrians the right-of-way. A forklift should never be driven on uneven grounds or on a highway. The driver should have a seat belt fastened all the time while driving.

Forklifts are an essential tool for the cultures which either consumes or makes mass-produced products. Forklifts would continue to remain necessary pieces of equipment for businesses. OSHA supervises compliance standards for businesses utilizing forklifts and provides certification and licensing protocols. The Forklift Rodeo is an entertainment event for operators and other employees which includes an obstacle course and other interesting spectacles.

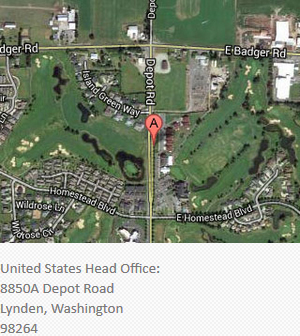

Contact Info

Questions or Comments